NanoTek

Most Critical Level Cleanroom Requirements

Nanotek is the classification for products used in environments that need to meet the highest level of cleanroom compliance.

Nanotek products meet ISO standards 3-4, and the federal standard classification 1-10 and are engineered to keep your cleanroom processes operating at the “consistent” state you require.

These products are used in front-end semiconductor fabs, aseptic operations, LED, biotech, nanotechnologies, and other emerging critical applications.

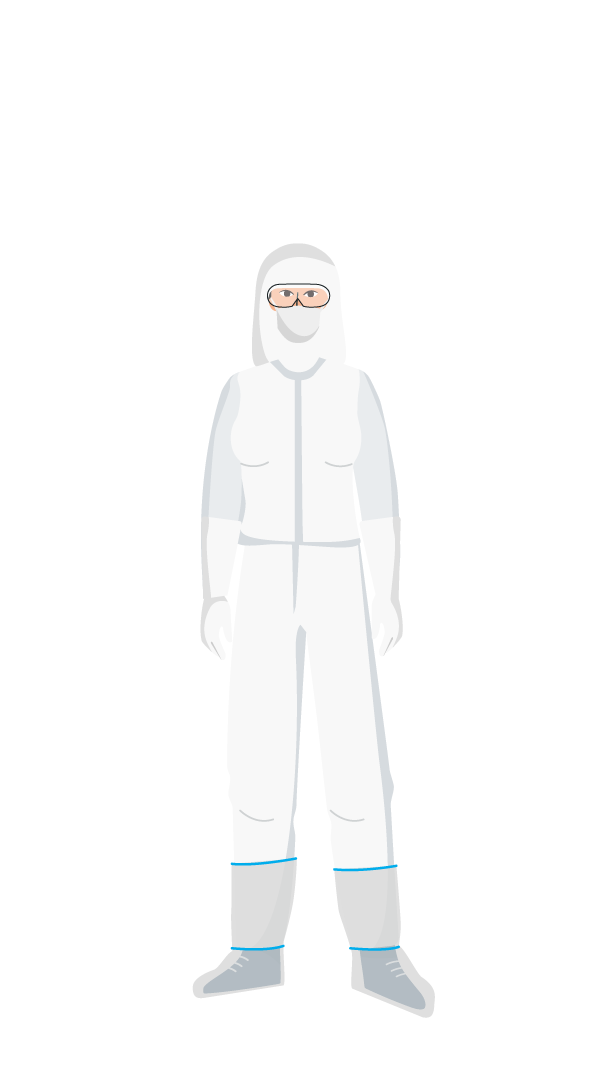

NanoTek Operator

Why Valutek?

Our Propositions

Class 1-10 (ISO 3-4)

Nanotek products meet the ISO standards 3-4, and the federal standard classification 1-10.

Market Segments

- Semiconductors/Microelectronics/MEMS

- Nanotechnology

- Aseptic Operations

- Emerging Critical Applications

- Pharmaceutical Research & Manufacturing

- Tissue Banks

NanoTek Products

- Gloves (12'' Long Cuff)

- Wipers

- Pre-wetted Wipers

- Apparel

- Adhesive Mats

- Mop Heads

- Cleanroom Tapes

- Cleanroom Notebooks & Papers

Defined Upper & Lower Limits

All Nanotek and Microtek products have defined upper and lower limits on particles and extractables published on their specific material specifications sheet.

Compliance

All Valutek products are compliant with both US Federal STD 209E and the EU ISO 14661-1 / 14698 Cleanroom Standards and our products must meet/exceed the published specification limits.

IEST Test Methods

Valutek materials are tested using IEST test methods to ensure fair & comparable data analysis, regardless of cleanroom classification. Do not be confused or misled by proprietary, non-repeatable test data, or Typical Published Value (TPV) results.

36-month Lot Analysis

Valutek is one of the industry’s first and only to publish a 36-month lot trending analysis and test data for all critical gloves, wipers, and apparel per repeatable IEST test methods.

Certificate of Compliance

Valutek provides a certificate of compliance reporting within 24 hours of your request.

Innovative Solutions for Critical Environments